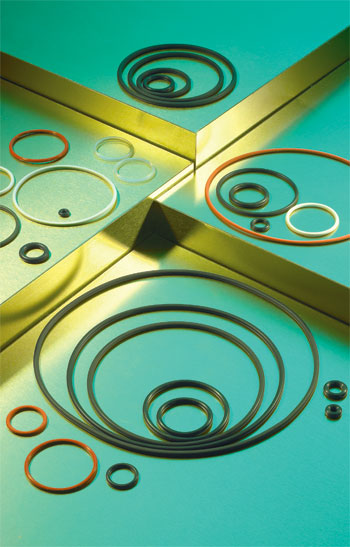

WHAT WE OFFER

Our Products

EPDM

EPDM (ethylene propylene rubber)

compound No. 2107 is excellent for hot water and steam service up to 325°F. It is very abrasion resistant and has excellent resistance to ozone, sunlight or weather and de-ionized water. EPDM also has good tensile strength and good resistance to mild acids, alkalis and alcohols. Rated -65°F to 350°F (short term to 400°F).

Silicone

Silicone Platinum cured compound No.

4749 (clear) material is known for its standard of purity and non-leaching characteristics. Its abilityto withstand many chemicals and combination of chemicals is the reason it is so popular with the pharmaceutical industry. Silicone has excellent low temperature flexibility — to 100°F in dry heat; 450°F is the top for continuous duty with 600°F possible for short periods. Rated at -80° to 400°F.

Viton

Viton® (bisphenol cured fluorocarbon

elastomer) compound No. 3207 material

has excellent mechanical, chemical, heat and steam resistance. It is particularly well-suited for hot fatty and oil products. Viton® is especially good for hard vacuum service because of its high molecular weight and low gas permeability. It has been used to -65°F in some static seals — flexibility,

0°F to 400°F under continuous duty and

will take 600°F for short periods of time. Rated at-20°F to 400°F (short terms to 600°F).

Buna-N

Buna-N compound No. 1107 material will

handle most food, dairy, and sanitary services. It is the backbone of the food and edibles industries, has excellent resistance to compression set, tear and abrasion. It has good acid and mild alkali resistance and is good for vegetable oil service.

Rated at -40° to 225°F.

CMPD

CMPD No. 2197 material will handle soft drink applications and is very well suited for products containing aspartame, Nutra– Sweet®.